- Phone: (616) 457-5999

- Toll Free: (800) 458-0590

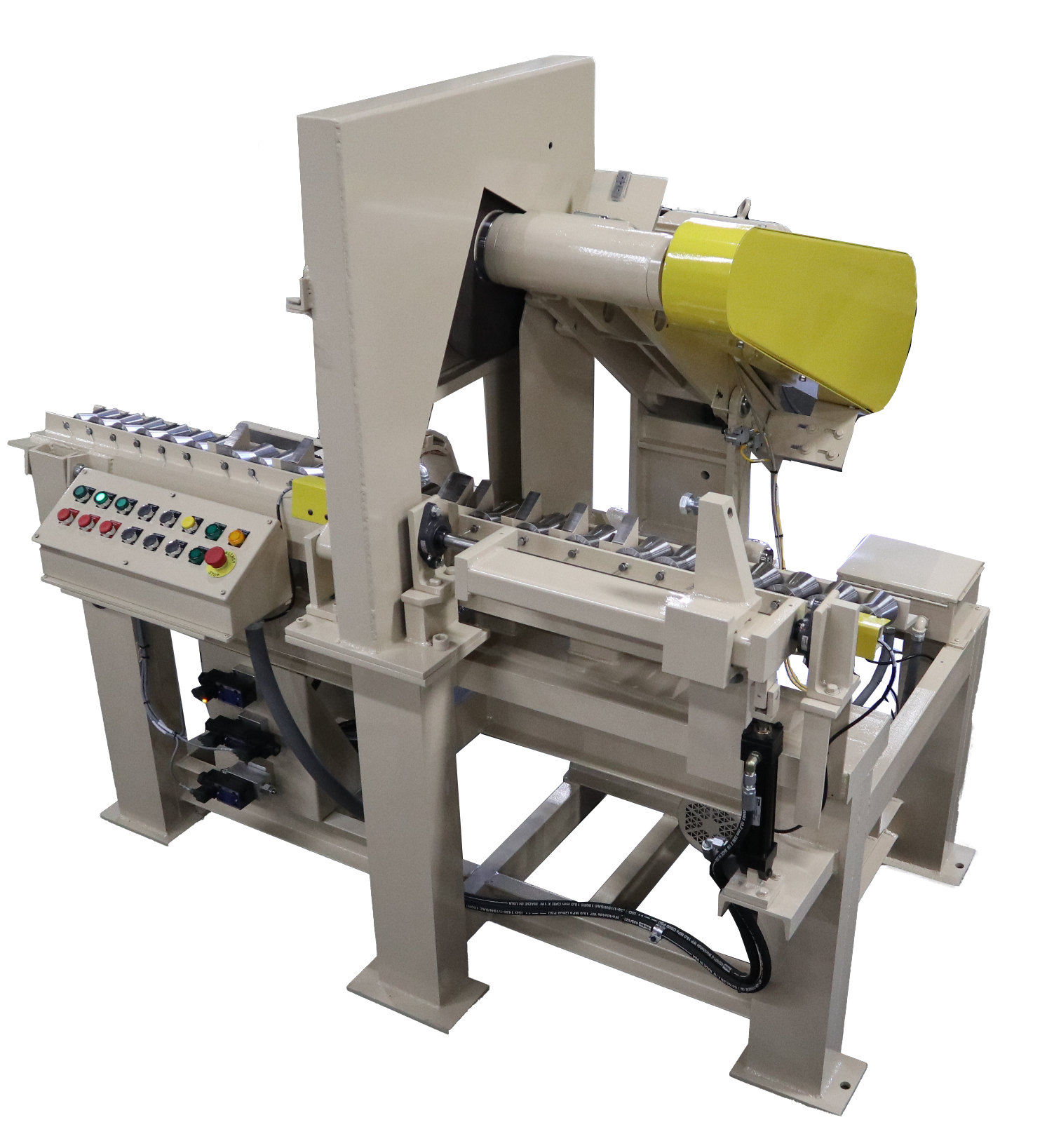

X300

X300

- 30hp drive motor

- 20” diameter cut off wheel

- 2 speed head module – this is designed for higher production where the wheel life, frequency of wheel change and machine efficiency are important. A 20” wheel operates at a spindle speed of 2,230 rpm’s which results in 12,000 sfpm, when the wheel wears down to approximately 16”, the surface speed is dropped to 9300 sfpm reducing cutting efficiency and increasing heat and wheel wear. At this point the sensor automatically signals the control panel to kick the constant speed horsepower motor into a higher speed and back to 12,000 sfpm restoring maximum efficiency.

- The model X300H is also equipped with heavy duty concave rollers. The bar stock is manually rolled through the blade area until it contacts and an adjustable outfeed stock set to the desired length. It will depress the clamp button which hydraulically lowers the bar stock into harden V blocks and automatically clamps the bar. Pressing the cut button hydraulically lowers the cut off wheel through the bar stock.

- This model will also have oscillation. Oscillation is typically used for heavy duty cutting jobs where the head moves back and forth through the cutting area. Oscillation will reduce loading and heating of the cutting wheel thereby making cutting faster and more efficient by not overloading the cutting wheel. It will also provide a much straighter cut with less kerf loss. It will improve wheel life and cut quality.

- The Model X300H will cut stock anywhere from 2” to 6” thick, will accommodate 5’ long pieces, and the cut off length is adjustable from 3” to 30”.

Tannewitz

X300 Specifications