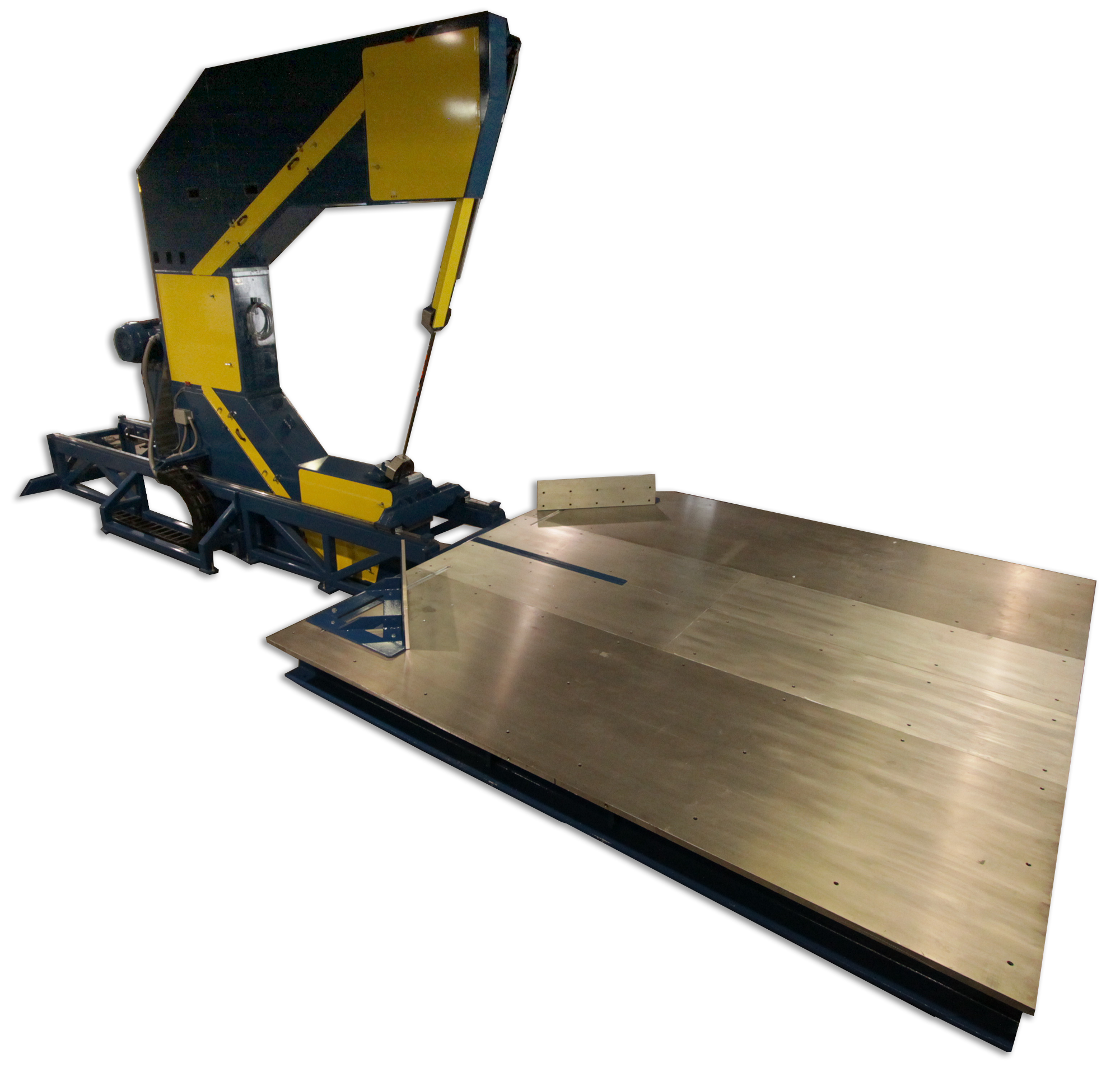

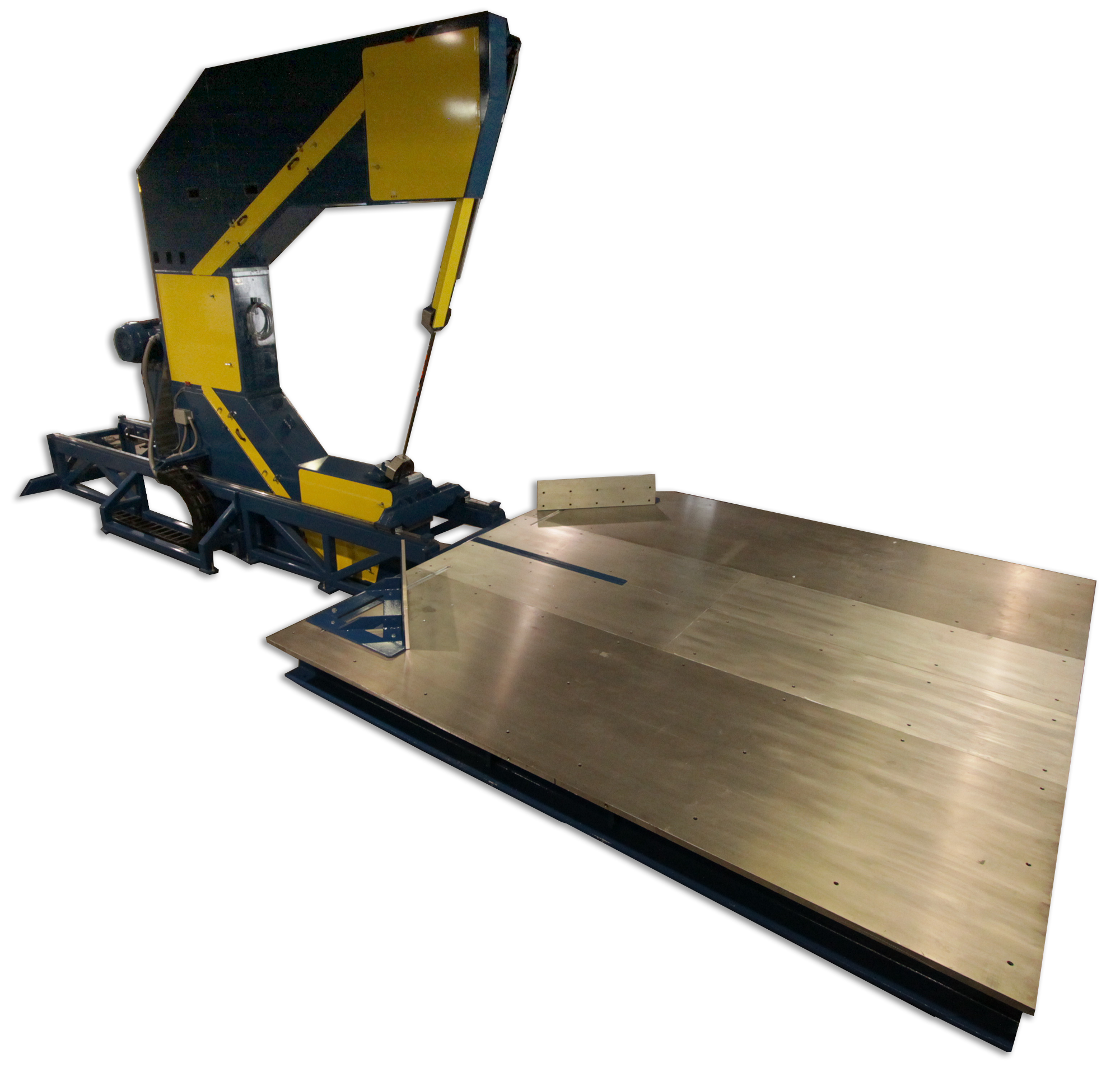

Giant Tire Cutting Bandsaw

Giant Tire Cutting Bandsaw

Tannewitz Tire Saw provides cost effective quality control for the tire manufacturers

The Tannewitz Model GV1NE Bandsaw provides tire manufactures the capability to cut out sections of finished product for quality control inspection. The unique variable speed (1000 – 6000 FPM) and special carbide grit blades enable both rubber and steel belted materials to be cut accurately and economically. Three models with 30”, 36” and 84” throats and under guide capacity from 16” through 72”, the Tannewitz GV1NE can handle not only passenger tires, but light truck and heavy off-road vehicle tires as well. A hydraulic powered table (0-30) tilts back to front to raise tires so that the cut starts at the top corner of the tread rather than across the whole face for a straighter cut.

Standard features include heavy-duty arc welded steel frame, automatic electric two wheel brake, 38 gallon recirculating coolant tank with chip collector and filter screen, dual coolant nozzles to flood both top and inside tire for added safety, variable blade speed (1000-6000 FPM) and NEMA 12 electrical controls

The Model GV1NE band saw incorporates Tannewitz’s 100 years experience in band saw manufacturing, and supported by extensive technical service and parts inventory.

Tannewitz

Giant Tire Cutting Bandsaw Specifications

Heavy duty arc weld steel frame

• Maximum capacity under the guides – 32”

• Throat capacity – 35 ½”

• Wheel diameter – 36”

• Blade width capacity – up to 1 ¼”

• Table size – 48” x 60” having 24” on each side of blade

• Table travel – 24”

• Table feed force – 0 to 350 lb.

• Table feed speed – 0 to 14 FPM

• Table tilts back to front to raise the tires so that the cut can be started at the top corner of the tread rather than across the whole face, getting a straighter cut, 0 to 30 degrees, hydraulically powered

• Blade length – will advise

• Upper wheel adjustment – 5”

• Hydraulic blade tension control mounted on the column of the band saw

• Automatic electric two wheel brakes, stopping the wheel in the event of blade breakage

• Tannewitz super rigid steel disc wheels with heavy duty shafts

• Tannewitz speedi-change demountable metalbacked rubber tires

• Heavy duty guide post – 1 ½” x 3”

• Hydraulic guide post operation

• Guide post travel – 32”

• Blade tracking control

• Tannewitz all steel roller guides – R472K

• Recirculating coolant with automatic paper feed filter

• Allen Bradley electrical controls with 110v push-button circuitry having a main fused disconnect ahead of all the electrical equipment

• Operator & maintenance manuals – 2

• 10hp inverter drive

• Control console movable in a 12’ lead with electrical and hydraulic control operated from console with the exception of saw blade tension

• Electric tachometer, showing blade speed in feet per minute