- Phone: (616) 457-5999

- Toll Free: (800) 458-0590

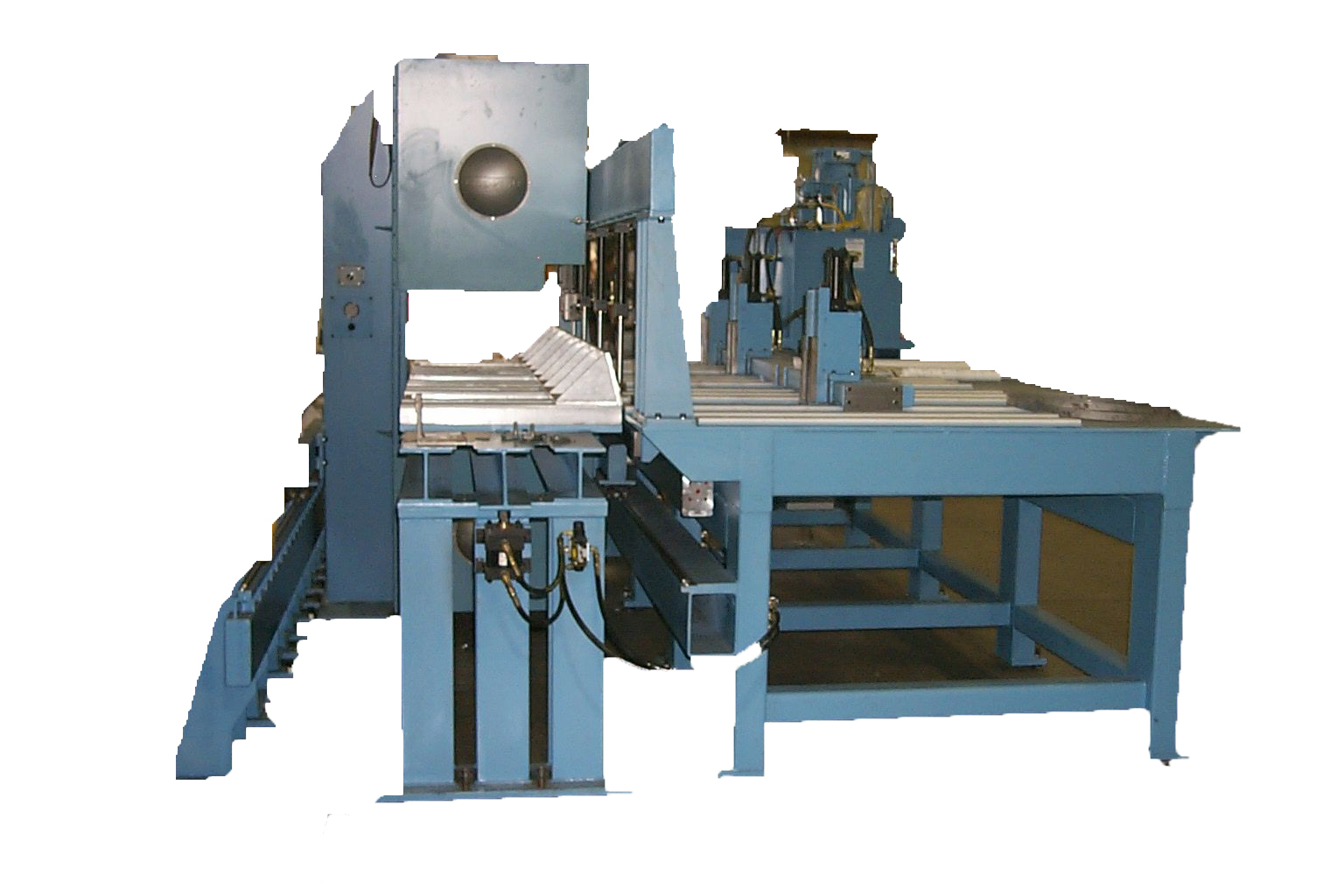

3000MH8

3000MH8

3000MH8

FEATURES:

MOVING HEAD PLATE SAW WITH AUTO INDEXING

The Mill Plate Saws can increase productivity and reduce costs in cutting tool steel, alloys and other non-ferrous materials. The unique construction of these band mills allow blade tensions to 35,000 psi for precise, vibration-free cutting. Available models feature completely automated, programmable sawing and DC indexing systems, the allow for unattended operation. Labor savings and accuracy are key to a fast payback.

Coupling Tannewitz quality with the latest sawing technology results in precise, accurate and repeatable cutting with minimal kerf loss.

In addition to these standard models, Tannewitz has built hundreds of special designs to meet specific customer requirements. Contact our Engineering Department concerning your particular application

Tannewitz

| Cutting Capacity | Blade | Blade Guide System | Blade Drive System | Blade Wheel Mechanism |

| Throat – 30″ | Width – Std – 1 1/2″ and 2″ | Movable Guide Arm – Hydraulic | Motor – will advise | Diameter – 30″ |

| Length – 13′ (156″) | Tensioning – Hydraulic – 35,000 PSI | Design – Side – Carbide | Blade speed range – 55 to 5000 SFPM | Thickness -1″ solid steel |

| Material Width – 60″ | Blade break shutoff – Std | back up – Bearing | Axles – 2″ diameter | |

| Material Height – 12″ | Chip Brush – Std – blade powered | Idle wheel bearing box – Cast Iron | ||

| hand scrapped | ||||

| Coolant System | Hydraulic System | |||

| Coolant – Acculube to include coolant reservoir pan | Hydraulic Motor – 5hp, 15gmp | |||

| Tank Capacity – 30 gal |

| Stock Feed: | |

| Type | Ball screw – stepper motor |

| Max Single Shuttle length | 30″ |

| Cut off width | Programmable – Std |

| # of pieces cut | Programmable – Std |

| Multiple job | Programmable – Std |

| Index clamps | 3 Standard |

| Hold down bridge clamps | 6 Standard |

| Weight capacity | 12,000 lbs |

| Jog control | Standard |

| Remnant length | 2″ |

| Machine Design | |

| Style | Moving head |

| Floor space requirements | 244″L x 161″W x 93″H |

| Machine weight | 14,000 lbs (approximately) |