- Phone: (616) 457-5999

- Toll Free: (800) 458-0590

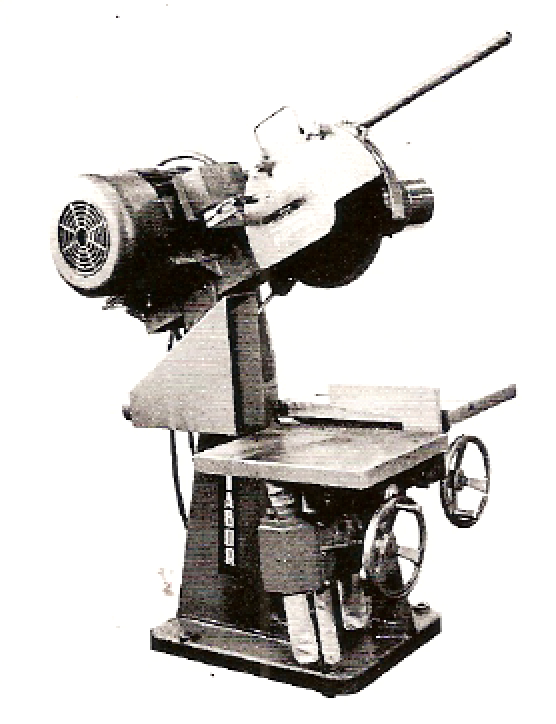

Split-Table (SPT) Module

Split-Table (SPT) Module

By far the most popular foundry machine in the industry, the Tabor Split Table base provides extreme flexibility, to support the widest possible variety of casting sizes and shapes.

The tables provide a total area 36 inches wide, 25 inches front to back, and may be adjusted a vertical distance of 9¼ inches as one unit, adjusted separately, or raised and lowered as a unity while the tables are at different levels.

All components are machined from rugged cast iron , and are designed to withstand the abusive environment of a foundry cleaning room.

The SPT base can be matched with any Tabor-Brasive head module.

Tannewitz

Split-Table (SPT) Module Specifications

| Tables |

Size – 36” x 25” (split pair) Max. adj. right table – 9¼” Max. adj. left table above right table – 3¾” Max. adj. left table below right table – 5½” Max. ht. floor to top of right table – 40½” Min. ht. floor to top of right table – 31¼” Max. ht. floor to top of left table – 44¼” Min. ht. floor to top of left table – 25¾” |

| Approx. Overall Machine Ht. |

16” wheel dia. heads with low trunnion – 71” 20”, 24”, 30” wheel dia. heads with high trunnion – 77” |

| Approx. Floor Space | 38” wide x 52” deep |

| Max. distance* between table and spindle centerline |

with low trunnion – 22” with high trunnion – 27¾” |

| Max. space* between new wheel and table |

16” wheel and low trunnion – 14” 20” wheel and high trunnion – 17¾” 24” wheel and high trunnion – 15¾” 30” wheel and high trunnion – 12¾” |